[ad_1]

Quality control has always been a critical aspect of manufacturing processes. Ensuring that products meet the expected standards is essential for customer satisfaction, regulatory compliance, and overall business success. Traditionally, quality control has been a manual and time-consuming process, relying on human inspectors to identify defects and deviations from specifications. However, with the advancements in artificial intelligence (AI) and machine learning, the landscape of quality control is rapidly changing.

The Role of AI in Quality Control

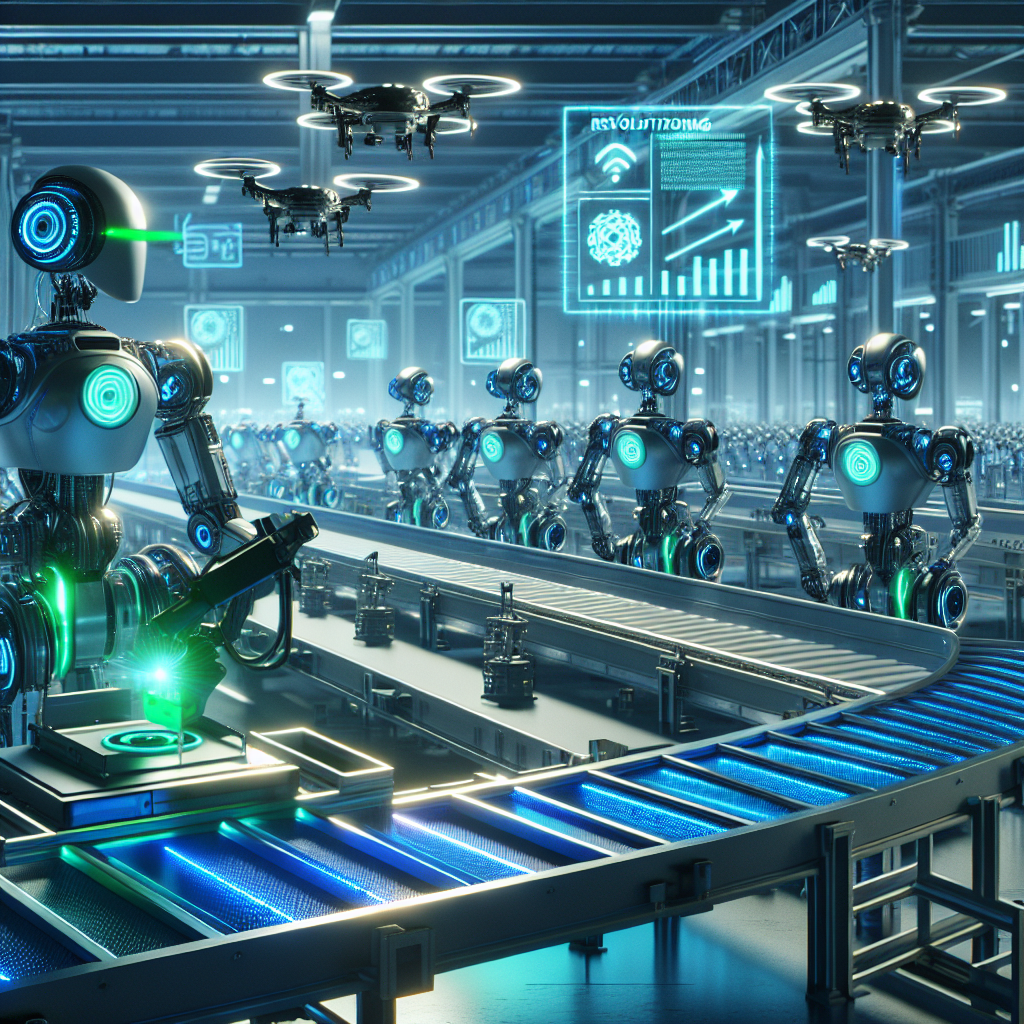

AI has the potential to revolutionize quality control in manufacturing in several ways. One of the key ways in which AI is transforming quality control is through the use of computer vision technology. Computer vision algorithms can analyze images or videos of products to detect defects or anomalies with a level of accuracy that surpasses human capabilities. This allows for faster and more accurate identification of quality issues, leading to improved product quality and reduced waste.

Another way in which AI is transforming quality control is through predictive maintenance. By analyzing data from sensors and machinery in real-time, AI systems can predict when equipment is likely to fail and schedule maintenance proactively. This not only reduces downtime and maintenance costs but also helps prevent quality issues that may arise from faulty machinery.

AI is also being used in quality control to optimize manufacturing processes. By analyzing data from various sources, including sensors, production lines, and supply chains, AI systems can identify patterns and trends that help manufacturers improve their processes and produce higher-quality products more efficiently.

The Benefits of AI in Quality Control

The use of AI in quality control offers several benefits to manufacturers. One of the primary benefits is improved product quality. AI systems can detect defects and deviations from specifications more accurately and quickly than human inspectors, leading to higher-quality products that meet or exceed customer expectations.

AI also helps manufacturers reduce costs by optimizing processes and preventing quality issues. By identifying patterns and trends in data, AI systems can help manufacturers streamline their operations, reduce waste, and improve efficiency.

Furthermore, AI can enhance the safety of manufacturing processes by predicting equipment failures and identifying potential hazards before they occur. This not only protects workers but also helps prevent costly accidents and downtime.

Challenges and Limitations of AI in Quality Control

While AI holds great promise for revolutionizing quality control in manufacturing, there are still challenges and limitations that need to be addressed. One of the main challenges is the need for large amounts of high-quality data to train AI algorithms effectively. Without sufficient data, AI systems may not be able to accurately detect defects or optimize processes.

Another challenge is the complexity of integrating AI systems into existing manufacturing processes. Manufacturers may face resistance from workers who fear job loss or lack the expertise to use AI systems effectively. Additionally, integrating AI into legacy systems can be costly and time-consuming.

The Future of AI in Quality Control

Despite these challenges, the future of AI in quality control looks bright. As AI technology continues to advance, we can expect to see even greater improvements in product quality, process optimization, and cost reduction in manufacturing. Manufacturers who embrace AI in quality control are likely to gain a competitive edge in the market and experience increased success in the long run.

Conclusion

AI is revolutionizing quality control in manufacturing by improving product quality, reducing costs, enhancing safety, and optimizing processes. While there are challenges and limitations that need to be addressed, the future of AI in quality control looks promising. Manufacturers who embrace AI technology are likely to experience increased success and competitiveness in the market.

FAQs

Q: How does AI improve product quality in manufacturing?

A: AI can detect defects and anomalies more accurately and quickly than human inspectors, leading to higher-quality products.

Q: What are the benefits of using AI in quality control?

A: AI helps manufacturers reduce costs, improve efficiency, enhance safety, and optimize processes.

Q: What are the challenges of integrating AI into manufacturing processes?

A: Challenges include the need for high-quality data, resistance from workers, and the complexity of integration into legacy systems.

Q: What does the future hold for AI in quality control?

A: The future of AI in quality control looks bright, with continued advancements in technology leading to greater improvements in manufacturing processes.

[ad_2]