[ad_1]

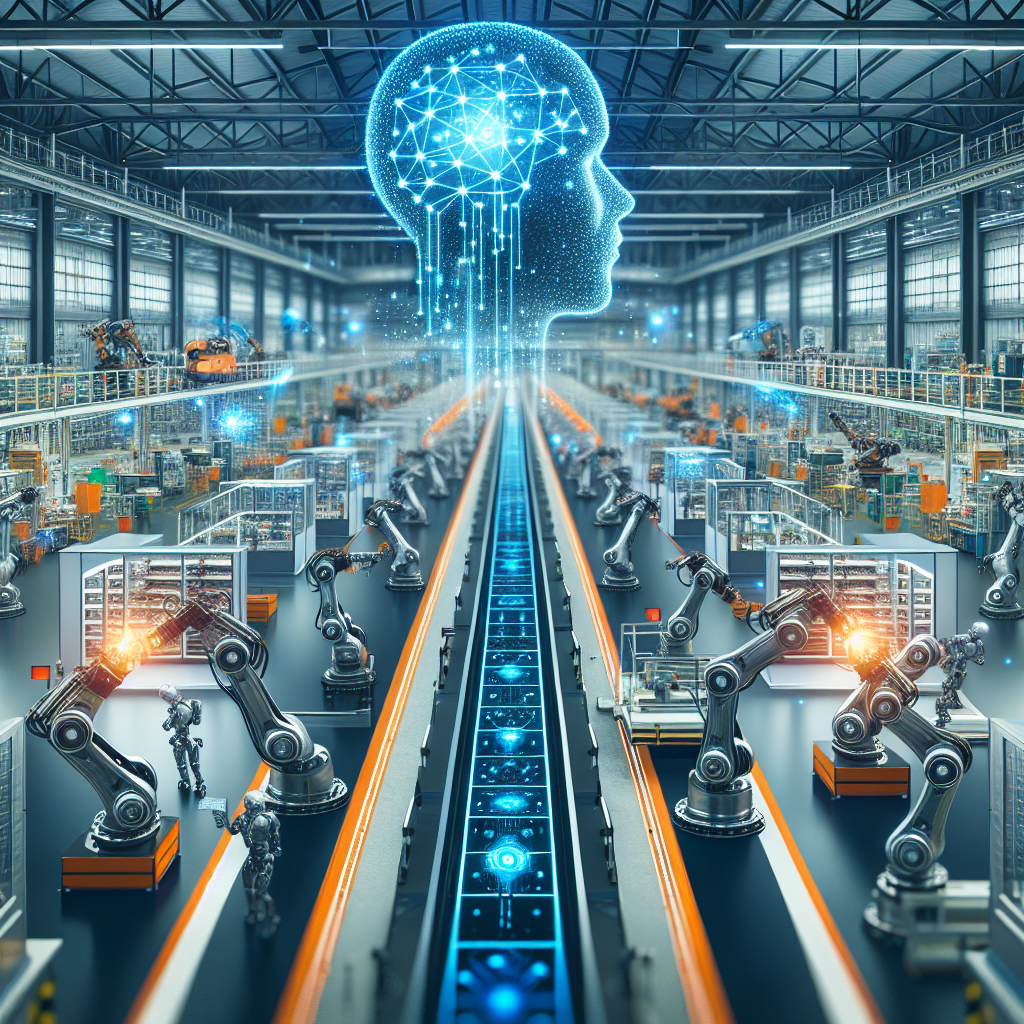

In the modern age, the manufacturing industry is constantly evolving to keep up with the demands of consumers and the advancements in technology. One of the most significant developments in recent years has been the integration of artificial intelligence (AI) in manufacturing processes. AI has revolutionized the way factories and production lines operate, and has brought about a new era of efficiency and productivity. This article will explore the impact of AI in modern manufacturing and how it has maximized efficiency in the industry.

The Role of AI in Modern Manufacturing

Artificial intelligence has rapidly become a fundamental component of modern manufacturing. With AI, machines and equipment are able to perform tasks that would have previously required human intervention. This includes a wide range of activities such as assembly, quality control, inventory management, and predictive maintenance. AI has the ability to analyze large sets of data in real-time, allowing manufacturers to make informed decisions and optimize their operations.

Improving Production Processes

One of the primary benefits of AI in modern manufacturing is the improvement of production processes. AI-powered machines can operate 24/7 without the need for breaks or rest, resulting in increased output and productivity. Additionally, AI can identify inefficiencies in production lines and make adjustments in real-time to minimize downtime and enhance overall operational efficiency.

Enhancing Quality Control

Quality control is a critical aspect of manufacturing, and AI has significantly enhanced the capabilities of manufacturers to maintain consistent quality standards. AI-powered inspection systems can detect defects and anomalies with greater accuracy and speed than human inspectors, leading to higher-quality products and reduced waste.

Optimizing Inventory Management

AI has also revolutionized inventory management in modern manufacturing. By analyzing historical data and real-time demand signals, AI systems can accurately predict inventory needs and optimize stock levels. This not only helps to prevent stockouts and overstocking but also minimizes storage costs and wastage.

Implementing Predictive Maintenance

Traditional maintenance practices often rely on scheduled inspections and replacement, regardless of the actual condition of equipment. With AI, manufacturers can implement predictive maintenance programs that use data analytics and machine learning to predict when equipment is likely to fail. This proactive approach minimizes unplanned downtime and prolongs the lifespan of machinery.

The Benefits of AI in Modern Manufacturing

The integration of AI in modern manufacturing offers a wide range of benefits that contribute to maximizing efficiency in the industry.

Increased Productivity

AI-powered machines can operate continuously and perform tasks at a faster pace than human workers. This results in increased productivity and output, allowing manufacturers to meet the demands of a competitive market.

Cost Savings

AI-driven automation and optimization lead to cost savings for manufacturers. By reducing the need for manual labor, minimizing waste, and optimizing resource usage, AI contributes to overall cost reductions in manufacturing operations.

Improved Quality and Consistency

The use of AI in quality control and inspection processes results in higher-quality products with fewer defects. Additionally, AI-powered machines can maintain consistent standards and precision in manufacturing processes, leading to improved product quality.

Real-time Decision Making

AI systems are capable of analyzing vast amounts of data in real-time, providing manufacturers with actionable insights and enabling them to make informed decisions quickly. This agility is crucial in responding to changing market demands and optimizing operations on the fly.

Enhanced Safety

AI-powered machines can handle hazardous tasks and work in environments that may be unsafe for human workers. This leads to improved workplace safety and reduced risk of accidents in manufacturing facilities.

The Future of AI in Manufacturing

The impact of AI in modern manufacturing is undeniable, and its significance will only continue to grow in the future. As technologies such as machine learning and robotics advance, the capabilities of AI in manufacturing will expand, leading to even greater efficiency, innovation, and opportunities for the industry.

Integration of Advanced Technologies

AI will continue to be integrated with other advanced technologies such as the Internet of Things (IoT) and big data analytics to further enhance manufacturing processes. This convergence of technologies will enable manufacturers to create more interconnected and intelligent production systems.

Personalized Manufacturing

AI will enable manufacturers to tailor products and processes to individual customer needs with greater precision and efficiency. This will lead to the rise of personalized manufacturing and mass customization, allowing companies to offer unique products at scale.

Ethical Considerations

As AI becomes more prevalent in manufacturing, ethical considerations surrounding the use of AI and automation will become increasingly important. Manufacturers will need to address issues related to job displacement, data privacy, and the responsible use of AI in decision-making processes.

Skill Development

As AI takes on more routine and repetitive tasks in manufacturing, there will be a growing need for workers to develop new skills and capabilities to work alongside AI-powered systems. This will require investments in education and training to ensure a skilled workforce that can harness the potential of AI.

Conclusion

AI has had a profound impact on modern manufacturing, revolutionizing the industry and maximizing efficiency in production processes. From improving production processes to enhancing quality control and optimizing inventory management, the benefits of AI in manufacturing are clear. As AI continues to advance, its role in manufacturing will only grow, leading to increased productivity, innovation, and opportunities for the industry as a whole.

FAQs

What are the main challenges of implementing AI in manufacturing?

Implementing AI in manufacturing can come with challenges such as high initial costs, technical complexity, and the need for specialized skills and knowledge. Additionally, integrating AI with existing manufacturing systems and processes can pose compatibility and coordination challenges. However, with careful planning and investment, these challenges can be overcome, leading to significant benefits for manufacturers.

What are the potential risks of AI in modern manufacturing?

While the benefits of AI in modern manufacturing are substantial, there are potential risks to consider. These include job displacement as AI takes over certain tasks, ethical considerations surrounding the use of AI and automation, and cybersecurity concerns related to the integration of AI with manufacturing systems. Manufacturers must carefully address these risks to ensure the responsible and effective use of AI in their operations.

How can manufacturers prepare for the integration of AI in their operations?

To prepare for the integration of AI in their operations, manufacturers should invest in staff training and development to build the necessary skills and knowledge for working alongside AI. They should also carefully assess their existing processes and identify areas where AI can bring the most value, and then develop a clear strategy for implementation and integration. Collaboration with AI technology partners and experts can also provide valuable insights and guidance.

What are the key considerations for choosing AI solutions for manufacturing?

When choosing AI solutions for manufacturing, key considerations include the compatibility of the AI system with existing technology infrastructure, the specific needs and goals of the manufacturing operation, the scalability and flexibility of the AI solution, and the potential for ongoing support and updates. Manufacturers should also consider the track record and reputation of AI solution providers to ensure high-quality and reliable performance.

[ad_2]