[ad_1]

Manufacturing has seen significant advancements in recent years, with the integration of artificial intelligence (AI) leading to revolutionary changes in the industry. From automated production lines to autonomous robots, AI is transforming manufacturing processes and paving the way for a more efficient and cost-effective future. In this article, we will explore how AI is revolutionizing manufacturing and the potential impact it may have on the industry.

Evolution of Automation in Manufacturing

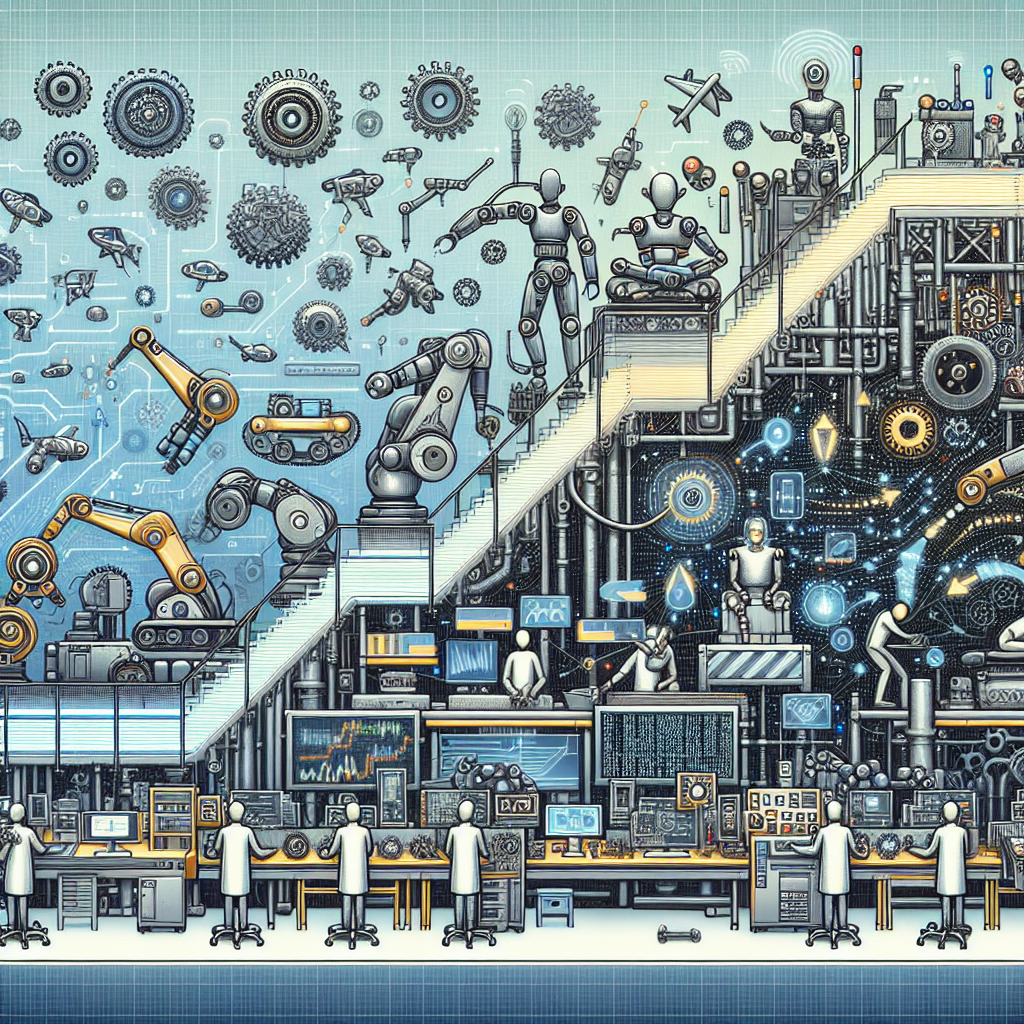

Automation has long been a staple in manufacturing, with the introduction of machinery and production lines streamlining processes and increasing efficiency. However, traditional automation systems were limited in their capabilities and required human intervention to operate effectively. With the advent of AI, manufacturing has entered a new era of autonomy where machines and systems can operate independently, making real-time decisions and optimizing production processes in ways that were previously unimaginable.

AI-Powered Robotics

One of the most significant advancements in manufacturing is the integration of AI-powered robotics. These intelligent machines are capable of performing complex tasks with a high degree of accuracy and precision, leading to increased productivity and reduced downtime. In addition, AI-powered robotics are also equipped with machine learning algorithms, allowing them to adapt to changing environments and optimize their performance over time.

Predictive Maintenance

AI has also revolutionized the way maintenance is performed in manufacturing facilities. Through the use of predictive maintenance algorithms, AI can analyze data from sensors and machines to predict when a component is likely to fail. This proactive approach to maintenance not only reduces the risk of unexpected downtime but also extends the lifespan of equipment, leading to significant cost savings for manufacturers.

Optimized Supply Chain Management

AI is also transforming supply chain management in manufacturing by providing real-time insights and predictive analytics. With the ability to analyze large volumes of data, AI systems can identify potential bottlenecks and inefficiencies in the supply chain, allowing manufacturers to make informed decisions and optimize their operations. This leads to improved inventory management, reduced lead times, and ultimately, lower costs for manufacturers.

Conclusion

As we have seen, AI is revolutionizing manufacturing in numerous ways, from autonomous robotics to predictive maintenance and optimized supply chain management. The integration of AI technologies has the potential to transform the industry, leading to increased efficiency, reduced costs, and improved competitiveness for manufacturers. As the technology continues to advance, we can expect to see even more innovative applications of AI in manufacturing, further reshaping the way goods are produced and distributed.

FAQs

What are the main benefits of AI in manufacturing?

AI in manufacturing can lead to increased efficiency, reduced downtime, improved quality, and lower costs. It can also provide valuable insights and predictive analytics to help manufacturers make informed decisions and optimize their operations.

Are there any potential challenges in implementing AI in manufacturing?

While the potential benefits of AI in manufacturing are significant, there are also challenges to consider, such as the initial cost of implementation, the need for skilled personnel to operate and maintain AI systems, and the potential impact on the workforce.

What is the future of AI in manufacturing?

The future of AI in manufacturing is promising, with continued advancements in technology leading to even more innovative applications of AI in production processes, supply chain management, and decision-making. As the technology matures, we can expect to see further improvements in efficiency, quality, and competitiveness in the manufacturing industry.

[ad_2]